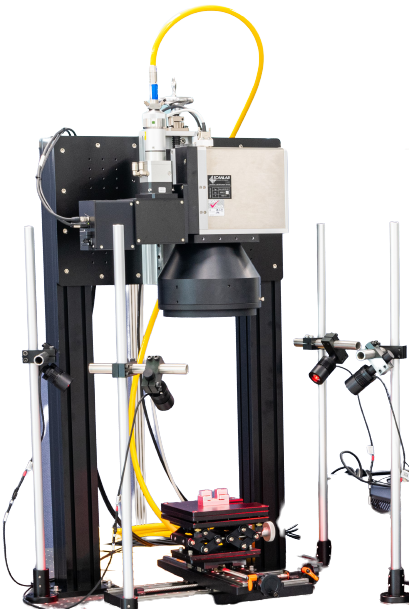

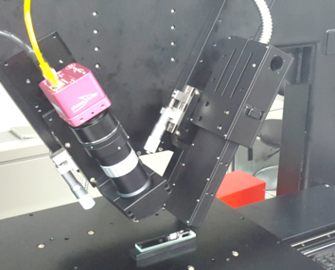

Precision Optical Modules

– Minimized back reflection

– Real-time monitoring

– Product position alignment

– Laser beam trajectory editing

– Automatic image & laser beam position correction

Applications

– Secondary battery welding and notching

– Semiconductor, PCB and automobile microprocessing: Welding, marking, cutting, soldering, etc.

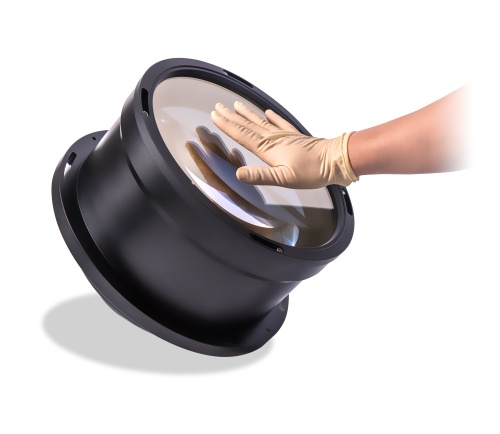

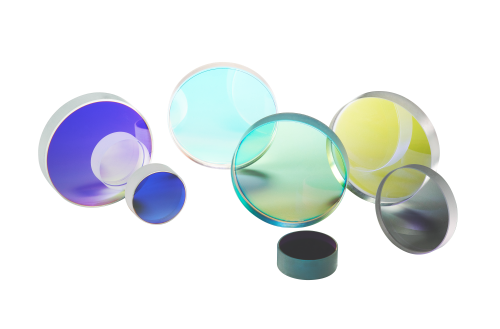

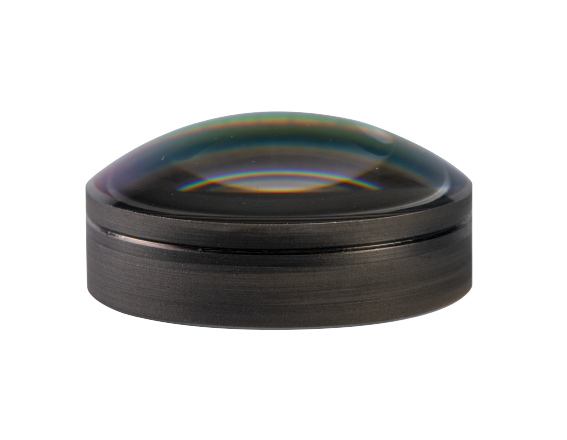

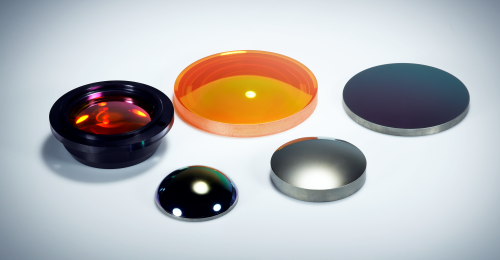

Lens Assembly

– Substrate Material

UV Grade Fused Silica, CaF2 , MgF2 , BK7, ZnSe, Sapphire, Ge, Crystal Quartz, Other material is available– Surface Quality, Surface Flatness

10-5 Laser Quality, l/20 at 633nm

– Damage Threshold

20J/cm2, 8nsec @ 1064nm typical

– Low loss, High damage threshold AR coatings available

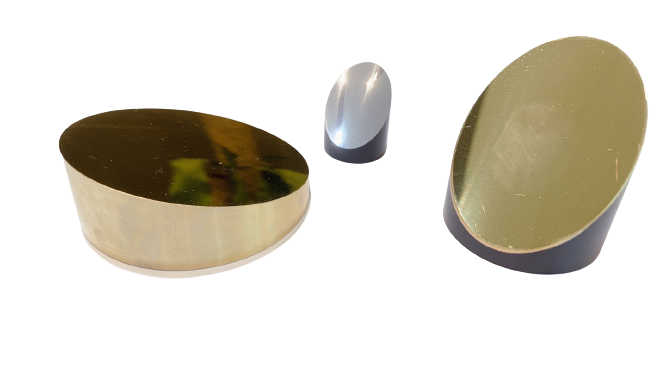

– Output Coupler Mirrors (Partially Reflecting Mirrors)

– Femtosecond Laser Mirrors

– Nd:YAG, Nd:YVO4 & Nd:YLF Laser Mirrors

– Solid State Laser Mirrors & Gas Laser Mirrors

– Excimer Laser Mirrors

– Broadband Metal & Dielectric Mirrors

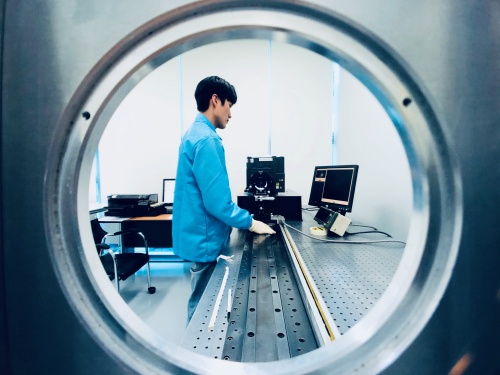

– Large window processing for ELA & LLO over 2000mm length

– Spherical lens processing over 500mm dia.

– Measurement system for large area by the 18inch interferometer.

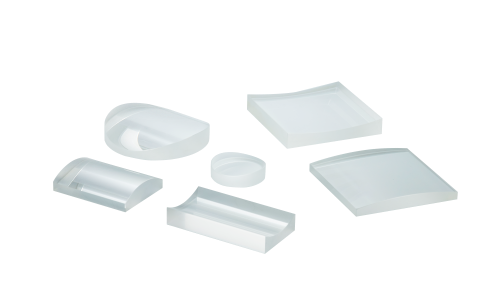

– Being used to compress, focus or expand the light in a single dimension.

– Applications for laser scanners, holography, optical information processing, spectroscopy, dye laser, and scanning focal microscopes.

– Capability of production for large cylindrical lens greater than 1500mm applicable for LLO & Annealing.

– Substrate Material

UV Grade Fused Silica, CaF2 , MgF2 , BK7, ZnSe, SF11, Other material is available

– Surface Quality & Surface Figure

20-10 Laser Quality, l/4 at 633nm

– Low loss, High damage threshold AR coatings available

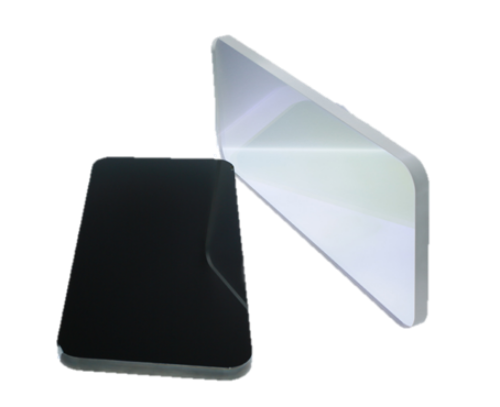

Defense & Aerospace Precision Optics

Size : 300mmdia (Negotiable)

Surface accuracy : 15nm(rms) 300mmdia / at 633nm (TWE)

Coating : VIS / NIR / MWIR Durable anti-reflection coating

Size : 400mmdia (Negotiable)

Surface accuracy : 30nm(rms) 300mmdia / at 633nm (TWE)

Coating : VIS / NIR / MWIR Durable anti-reflection coating

Surface accuracy : 60nm (rms)

per 100mmdia at 633nm

anti-reflection coating

– Ultra-precision processing and measurement can be provided for special cases.

Surface accuracy : 20~30nm(rms) 300mmdia / at 633nm (TWE)

Coating : VIS / NIR / MWIR / LWIR Durable anti-reflection coating

Customized Service

|

Ion Beam Sputtering – Wavelength(nm) : 240nm – 3000m |

Advantages of IBS • High durability |

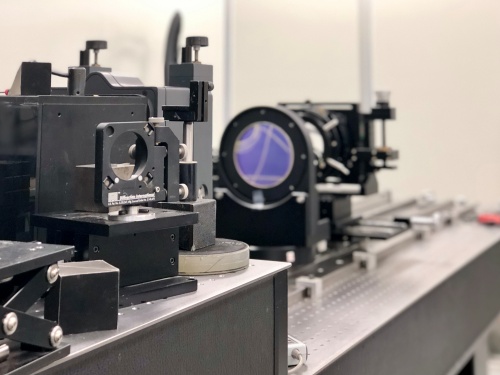

High-precision high reflectivity measurement compared to reflection + transmission + absorption measurement

– High reflectivity measurement using resonator method [355,532,1064nm]

– High-reflection mirror’s reflectivity of 99.9995% can be measured.

– Lens measurement at various angles of incidence: 5-45º

– Measurement of s and p-pol

Reference page : GLACIER® https://www.ultrafast-innovations.com/devices/GLACIER.html

2. Advanced Processing & Measurement Areas (MRF, ASI, IBF )

CNC Grinding machine (G1-2P)

Benefits :

-

Working range(mm) : Spiral (Φ500)_Asphere

Raster (380 x 250)_Rectangular - Axis repeatability : +/- 0.001mm

- Axis range(mm) : X(380), Y(580), Z(250), A(+90°/-30°), S1(10000rpm), C1(600rpm)

- Availability : Sphere, Asphere, Off-Axis-Parabolic(OAP), Freeform, Cylinder, edge, chamfering

CNC Polisher (MCP 251)

Benefits :

- The large range of usable tools like Polishing Wheel (Wheel Polishing Technology), Active Fluid Jet Polishing (A-FJP), different pitch tools

- Direct interface to tactile and optical surface measuring systems like Taylor-Hobson Form Talysurf, Mahr MarSurf, Mitutoyo or OptoTech Interferometers

-

Use of conventional consumables

(e.g. Cerium oxide as polishing medium, polyurethane as polishing medium carrier)

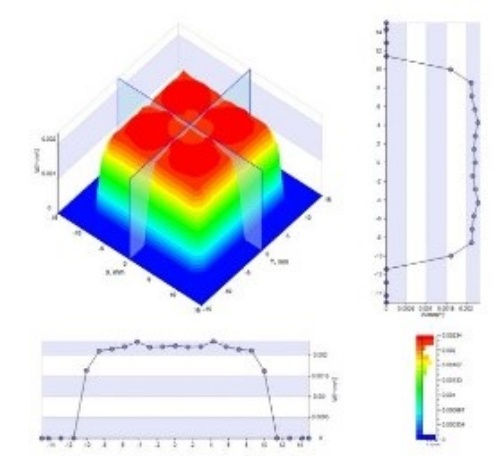

MRF (Q-flex 300)

Benefits :

- Provides a completely deterministic process that can be characterized to very high precision

- Significantly reduces cycle times due to its high rate of removal and maintains process stability

- Correction of transmitted wavefront (windows, phase plates, entire system correction on one surface)

- Optical glasses, single crystals (calcium fluoride, silicon…) and ceramics

- Square and rectangular aperture surfaces such as prisms, cylinders, and photoblank substrates

- High-aspect-ratio optics and substrates (thin film filters, etalon substrates, semiconductor wafers etc.)

- Removing micro-cracks and subsurface damage and improving glass resistance to laser damage

Reference Pages : Q-flex 300 : https://qedmrf.com/en/mrfpolishing/mrf-products/q-flex-300

MRF Application : https://qedmrf.com/en/mrfpolishing/mrf-applications

ASI (ASI(Q)-VON, Freeform)

Benefits :

- Improved accuracy _ automatically calibrates systematic instrument errors.

- Flexible, to minimize custom tooling and lead time

- Automated and easy-to-use

- Capable of testing aspheres without dedicated nulls

-

Freeform metrology software

- Enables interferometric measurements of freeform optics, without the use of a null lens

- measure a wide variety of freeforms including toroids, heads-up display optics, and off-axis sections of rotationally-symmetric optics

Reference Pages : ASI(Q) : https://qedmrf.com/en/ssimetrology/ssi-products/asiq

ASI(Q) application : https://qedmrf.com/en/ssimetrology/ssi-applications

– Maximum measured diameter: 400mm

– Lens centering measurement accuracy : 0.1μm

– Lens centering measurement: 40 surfaces (20 lenses)

– Air Gap Measurement : 800mm

– Effective Focal Length (EFL)

– Back Focal Length (BFL)

– Radius of curvature

– IR lens & cylindrical lens measurement

– Modulation Transfer Function (MTF) on-axis

– Aspheric eccentricity measurement

Manufacturing Tolerance Chart

| Commercial(A,B) | Precision(A,B,C) | High precision | |

| Diameter(mm) | +0/-0.100 | +0/-0.025 | +0/-0.010 |

| Center thickness(mm) | ±0.100 | ±0.050 | ±0.020 |

| SAG(mm) | ±0.05 | ±0.025 | ±0.01 |

| Clear Aperture | 85% | 90% | 90% |

| Tolerance of radius of curvature (larger of two) | ±0.1%/5fr | ±0.05%/3fr | ±0.02%/1fr |

| Irregularity-interferometer(PV) | 1λ, λ/2 | λ/4, λ/6, λ/10 | λ/20 |

| Centering (Beam deviation) | 3 arcmin | 1 arcmin | 0.3 arcmin |

| Scratch Dig | 60-40 / 40-20 | 40-20 / 20-10 / 10-5 | 10-5 |

| Surface Roughness(Å rms) | 10 | 7 | 5 |

| Commercial | Precision | High precision | |

| Diameter(mm) | ±0.10 | ±0.05 | ±0.03 |

| Center thickness(mm) | ±0.10 | ±0.05 | ±0.01 |

| Tolerance of radius of curvature (larger of two) | ±0.1%/5fr | ±0.05%/3fr | ±0.02%/1fr |

| Surface form (Irregularity, PV) | 2um | λ/2 | λ/8 |

| Rotational invariant irregularity | 0.8um | λ/4 | λ/12 |

| RMS irregularity (RMSi) | 0.6um | λ/6 | λ/30 |

| Slope tolerance | 180arcsec/1mm | 40arcsec/1mm | 12arcsec/1mm |

| Edge thickness variation | 25um | 15um | 5um |

| Tilt angle of the aspheric surface to the second surface | 2.5 arcmin | 1.0 arcmin | 0.5 arcmin |

| Lateral displacement of the aspheric to the edge of the lens | 0.02mm | 0.015mm | 0.01mm |

| MIL-Scratch/Dig | 60-40 | 40-20 | 20-10 |

| Surface Roughness(rms) | 3.0nm | 2.0nm | 0.5nm |

이용약관 | 이메일무단수집거부 | 개인정보처리방침

업체명: 한국전광(주) | 대표 : 유해귀 |

주소 : 인천광역시 계양구 서운산단로2길 36

사업자번호 :130-81-07467 | 대표전화 : 032-673-6114 | E-mail : korsales@keoc.kr

Copyright © 한국전광(주). All Rights Reserved.